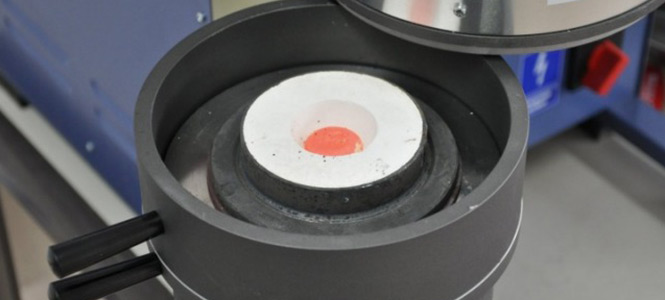

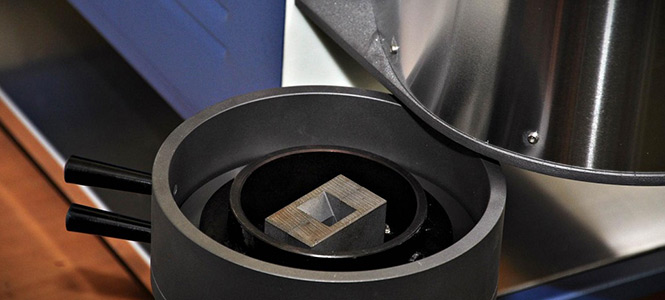

Agatronic H vacuum induction casting machine is a unit based on the AFI-03 induction furnace, just as Agatronic G casting machine. However, this machine has got a much bigger crucible capacity, as well as 100% more generator power. Unlike in Agatronic G casting machine, those parameters let the user cast much heavier objects during a one-time session. What is more, the machine can be characterized as having greater work dynamics and some other functions of the granulator which make it possible to let the alloy flow through the graphite sieve with seven openings. This kind of operation guarantees obtaining more homogeneous granulate in much shorter time.

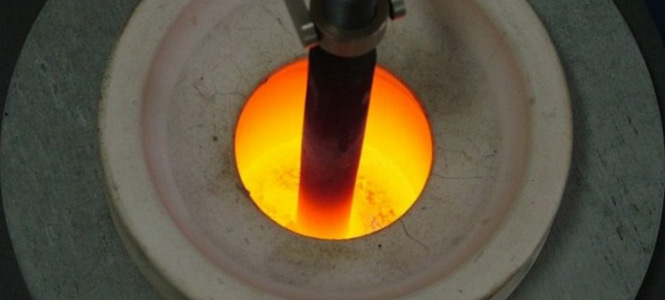

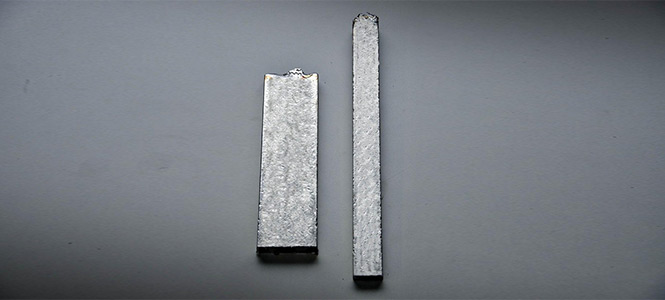

The unquestionable advantage of the machine is the possibility of the bottom drain metal-sheets casting in the vertical mold.

Agatronic H casting machine main features can be described as:

• Substantial work dynamics thanks to the application of inductive heating

• High density of the alloy achieved by mixing with the use of magnetic field (inductive mixing)

• Ergonomical structural solutions

• Low maintenance costs

The undeniable merit of the bottom drain metal-sheets casting method is the difference in metal densities and their contamination. When metal changes into liquid, all of the dirt comes into the surface. During the casting out of, so called ‘hand’, all the pollution gets into the mold and it becomes the part of the mould. When we cast metal through the opening in the crucible, the dirt is left in it or it stays in the mold opening. The product casted in this way has got a more cohesive structure and it is easier to roll. The additional good point of the machine is the uniform, constant and uninterrupted stream of metal.